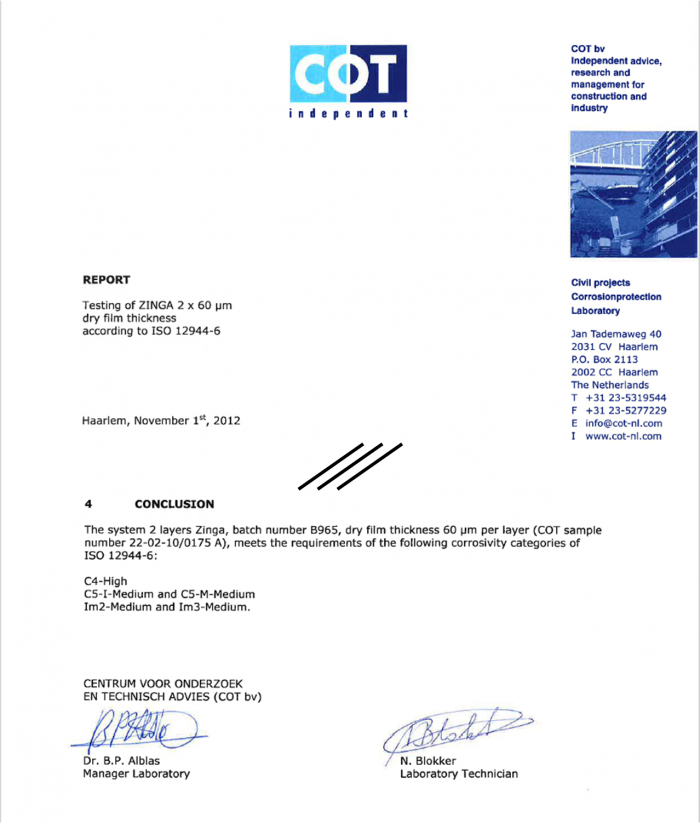

ISO 12944 on ZINGA + Zingaceram HS + Zingaceram EP

ISO 12944-6: Paints and varnishes — Corrosion protection of steel structures by protective paint systems

The ISO 12944 standard is intended to assist engineers and corrosion experts in adopting best practice in corrosion protection of structural steel with coatings at new construction and repairs. ISO 12944 is progressively superseding regional standards to become a truly global benchmark in corrosion control.

The ZINGA/Zingaceram HS/Zingaceram EP system has been subjected to extensive testing such as water condensation

test, neutral salt spray test, chemical resistance test and water immersion test. After a prescribed exposure test (depending on representative environment), the coating is assessed for adhesion, blistering, rusting, cracking and flaking.

Environments are classified according corrosivity:

- C1: Indoor conditions (Heated buildings/neutral atmosphere)

- C2: Rural areas, low pollution (countryside, inland town areas)

- C3: Urban and industrial atmospheres with moderate sulphur dioxide levels and salinity. Production areas with high humidity (inland big cities with high traffic)

- C4: Industrial or coastal (with moderate salinity) zones (chemical factories, swimming pools, shipyards)

- C5I: Industrial zones with high humidity and aggressive environment (continuous condensation and high pollution)

- C5M: Coastal zones and marine zones with high salinity (continuous condensation and high pollution)

After exposure, the coating is evaluated as H(igh), M(edium) or L(ow); reflecting in a life expectancy of:

Low: Life expectancy less than 5 years

Medium: Life expectancy between 5 and 15 years

High: Life expectancy more than 15 years

The system

ZINGA 1 x 60-80 µm DFT

+

Zingaceram HS 1 x 120 µm DFT

+

Zingaceram EP 1 x 60 µm DFT

passed the tests for C5I and C5M with a High Classification.