PSA Lighting Masts

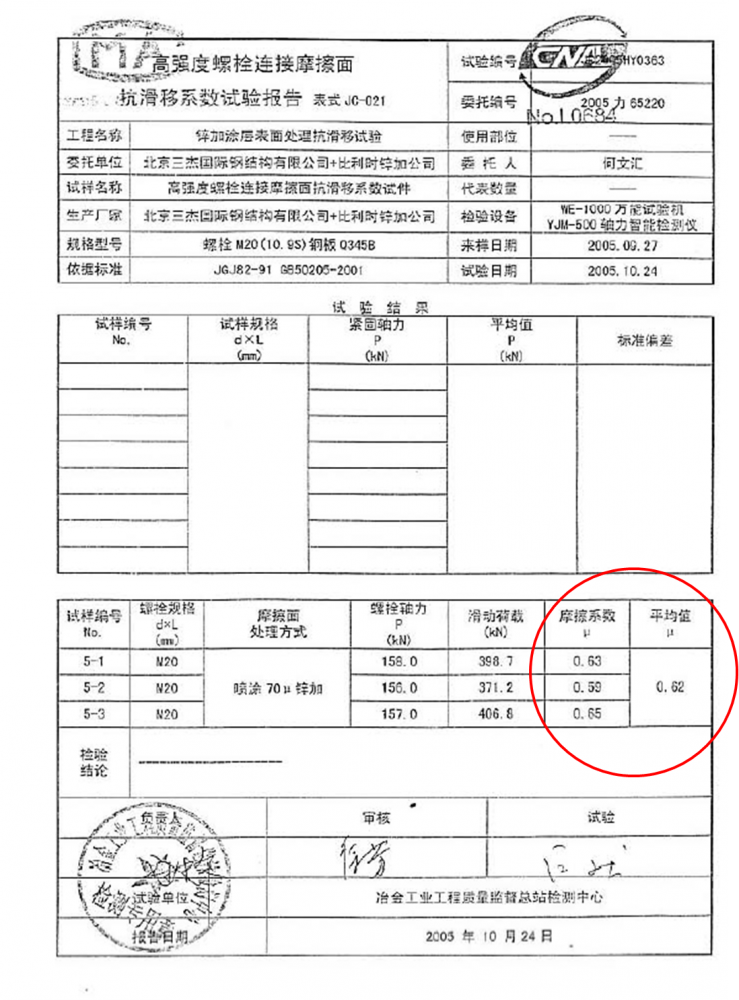

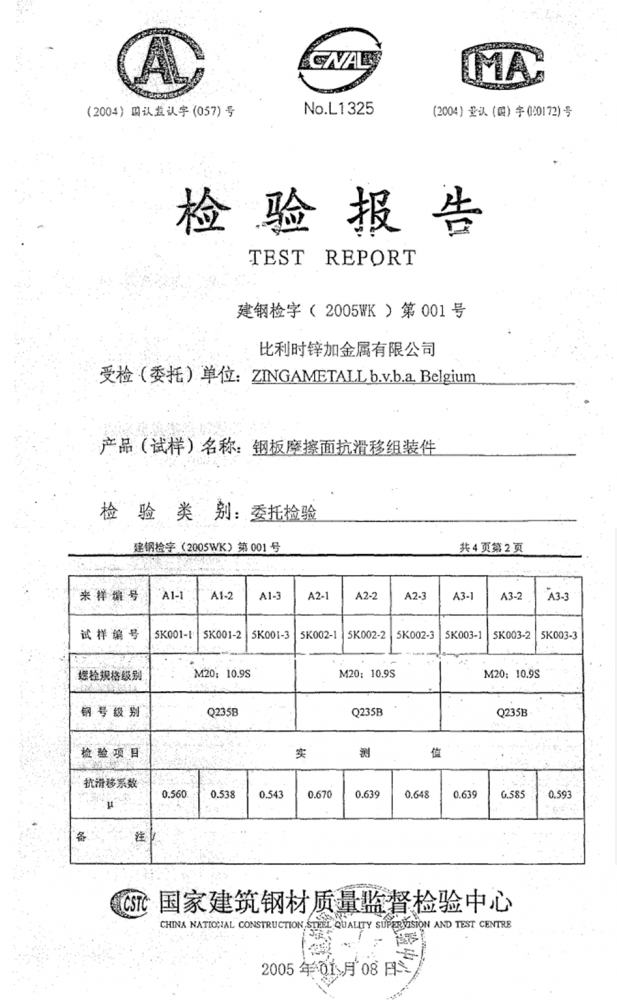

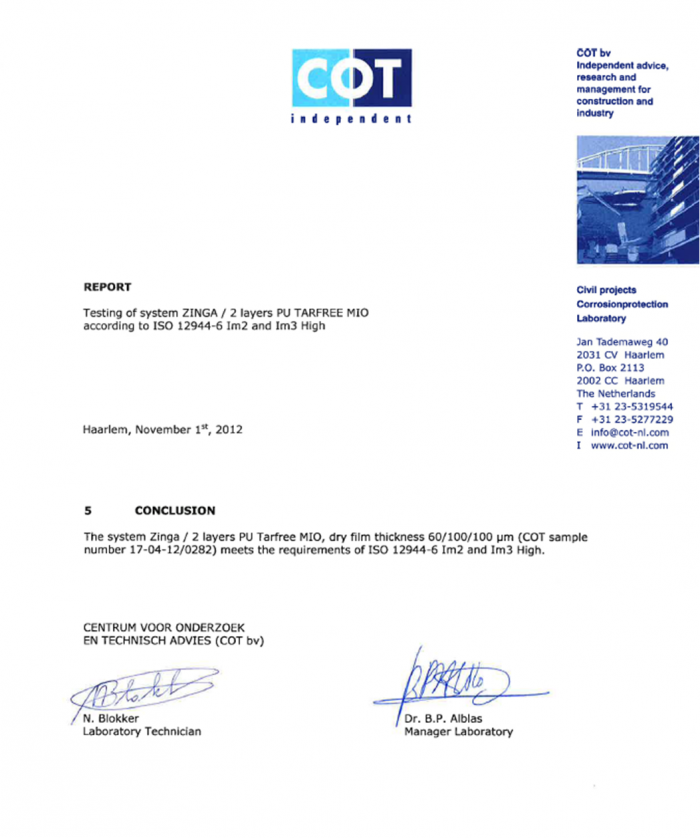

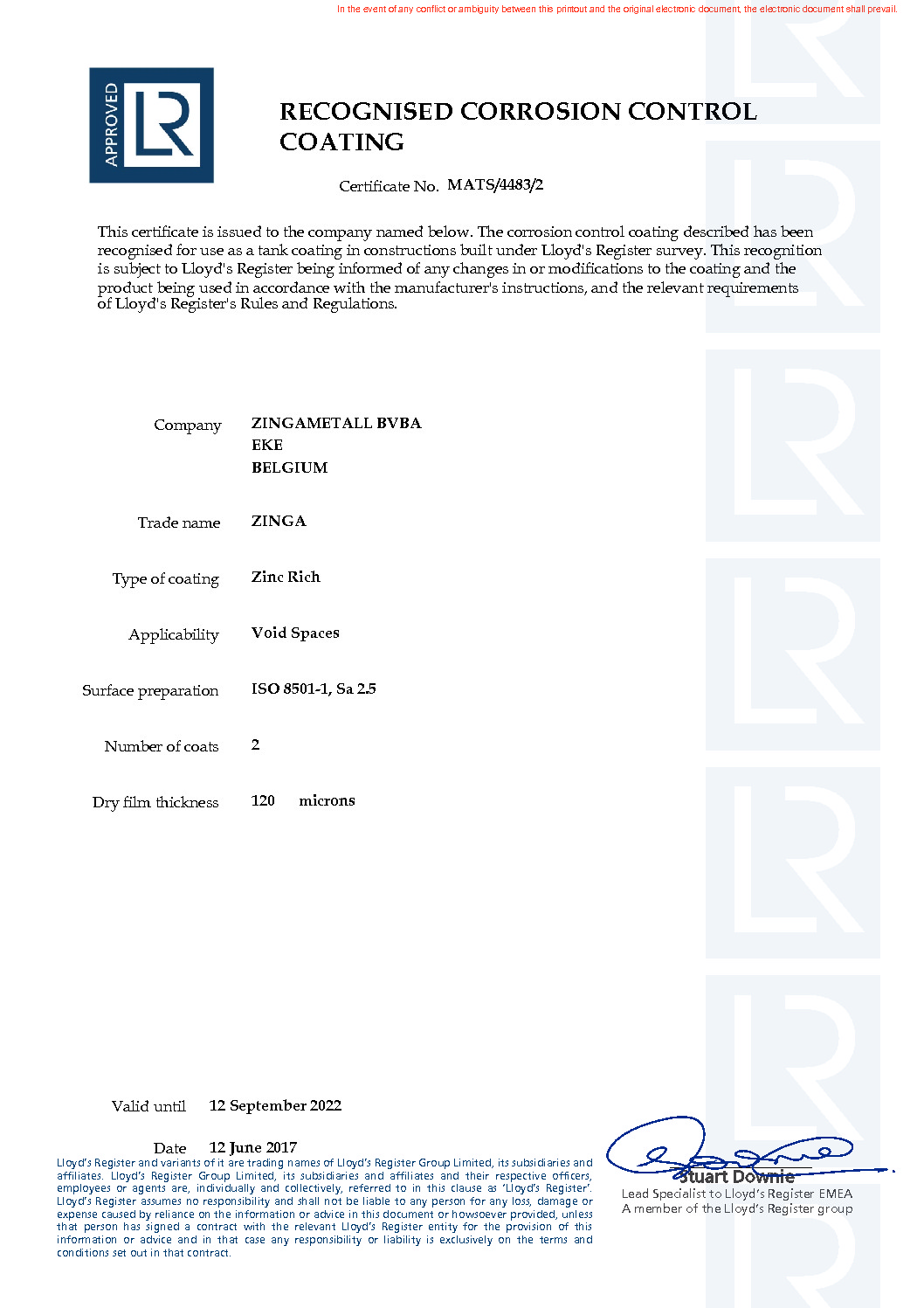

PSA (Port of Singapore Authority), is the 4th largest port in the world and the second busiest after Rotterdam. ZINGA was selected to be coated on 30 lighting masts.

Each lighting mast measures 45 meters in height within minimum DFT of 120 microns.

At this moment 90% of the light masts in this harbor are protected with ZINGA . The first light masts were treated in 2002.

Being at the container area, most of the lighting masts (previously protected by hot-dip) were installed near to the sea coast and were found to be quite rusty.

- Lighting Mast before ZINGA application (old HDG)

- Lighting Mast treated with ZINGA showing relative size

- Lighting Mast treated with ZINGA

- Lighting Mast treated with ZINGA

- Nuts and Bolts treated with ZINGA